BLACKSBURG — One of the world’s largest tractor manufacturers is planting a flag in Blacksburg, opening an office in the Virginia Tech Corporate Research Center and moving senior level staffers here to create a technology development outpost.

India-based Mahindra & Mahindra has not said how many employees it plans at the CRC. But Rajesh Jejurikar, president of the company’s farm equipment business, said it will have a “strong on-ground presence in Blacksburg” focused on developing new products for sale in North America.

The company, which outpaces competitors like John Deere in global tractor sales with revenue above $3 billion, has also solidified a deep research relationship with Virginia Tech.

The first joint endeavor with university researchers will be to explore the creation of a grape-picking robot to add to Mahindra’s farm equipment lineup.

And the company expects other joint projects.

Both Mahindra announcements follow years of courtship by Tech as it tries to attract billion-dollar industry giants from around the world to rural Southwest Virginia. A similar effort brought Hewlett Packard Enterprise to town in 2016.

Guru Ghosh, Tech’s vice president for Outreach and International Affairs, said the Mahindra relationship began around 2013, when the university established a presence in Chennai, India. It’s a small office today with a handful of university employees, but the research center serves as a starting point for these kinds of initiatives.

Tech employees there met with Mahindra from time to time, planting seeds along the way about ways the two could collaborate.

“Globalizing Blacksburg and globalizing Virginia is fundamental to a research university that now has its tentacles all over the world,” Ghosh said. “I think this is just the start of an expansion of Mahindra’s presence in Virginia.”

Jejurikar, of Mahindra, said North America is the company’s largest market for tractors outside of India, and it wants to use technological developments to keep growing here.

The company already has a handful of manufacturing facilities in the U.S. It’s known for its red tractors, from small models to plow snow up to large ones for farming. In India, the brand is also one of the largest automobile manufacturers.

Mahindra considered numerous universities before choosing a partner for its North American tractor research hub.

Jejurikar said Blacksburg was chosen for its proximity to farming communities and for Virginia Tech’s reputation in fields he believes will be useful in the agricultural industry, including robotics, artificial intelligence and mechanical engineering.

The office will be called the Mahindra Agricultural Technology Center at Virginia, or MaTC@Virginia.

Jejurikar declined to comment on employment figures or how much the company is paying Virginia Tech for the research collaboration, citing regulatory laws that bar the company from commenting on corporate matters ahead of investor meetings.

“We are serious about it and would like to really leverage this to build our global strategy,” Jejurikar said via telephone from Mumbai.

Virginia Tech researcher Tomonari Furukawa has already begun working on the university’s first project for Mahindra.

He said wine grapes are pretty simple to harvest autonomously, since they can be shaken from the vine and collected. But tabletop grapes, or the kind you buy at the grocery store for snacks, need to be more delicately handled. They have to be wrapped so they’re protected from sun damage and — typically — cut from the vine by hand.

Furukawa wants to develop a robot that can see the grapes, navigate sloped, often muddy terrain and carefully cut grapes from the vine. One day, the technology could be integrated into Mahindra’s tractors to save farmers time and money.

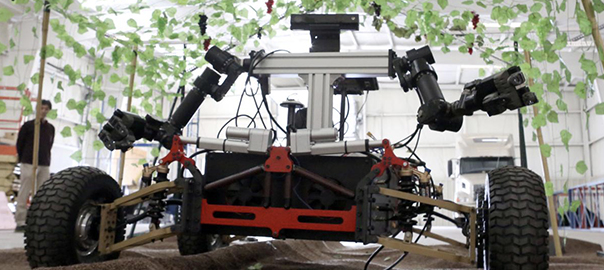

The university does have a prototype that it’s using as a starting point for the project. It’s a small vehicle with wheels designed for rough terrain. It has two arms that can reach out to grab the fruit.

Right now, the robot is controlled remotely with a joystick. Operators have to get the machine close to the grapes, and then the robot takes over from there.

Furukawa said his team is taking an assistive robotics approach. Farmers will use the machines to make the work easier instead of letting robots take over altogether. As the technology develops, operators will do less and less.

“Something that’s still difficult for the technology to do, we will ask humans to do it,” Furukawa said. “That is the approach so that we can start to introduce robots to harvesting.”